Oxide Scale Behavior in High Temperature Metal Processing

ISBN: 9783527325184 出版年:2010 页码:388 Michal Krzyzanowski John H Beynon Wiley

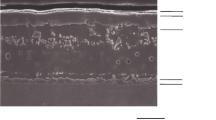

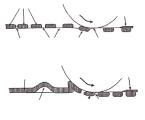

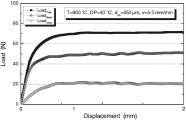

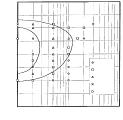

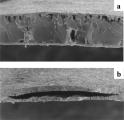

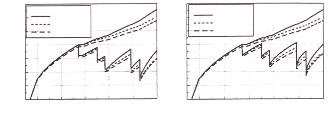

1. INTRODUCTION 2. ROLE OF SECONDARY OXIDE SCALE DURING HOT ROLLING AND FOR SUBSEQUENT PRODUCT QUALITY Friction Heat Transfer Thermal Evolution in Hot Rolling Secondary Scale Related Defects 3. SCALE GROWTH AND FORMATION OF SUBSURFACE LAYERS High Temperature Oxidation of Steel Formation and Structure of the Subsurface Layer in Aluminum Rolling 4. METHODOLOGY FOR NUMERICAL CHARACTERISATION OF THE OXIDE SCALE IN THERMOMECHANICAL PROCESSING Combination of Experiments and Computer Modelling: A Key for the Scale Characterisation Prediction of Mild Steel Oxide Failure at Entry into the Roll Gap: Evaluation of Strains, Tensile Failure, Steel Oxide Failure, Scale Failure, Verification 5. MEASURING OXIDE SCALE BEHAVIOUR UNDER HOT WORKING CONDITIONS Laboratory Rolling Experiments Tensile Testing Hot Four-Point Bend Testing Hot Tension Compression Testing Bending Testing 6. NUMERICAL INTERPRETATION OF TEST RESULTS Measurement of Separation Loads within the Scale/Metal System Mathematical Model and Interpretation of Experimental Results 7. PHYSICALLY BASED FINITE ELEMENT MODEL OF THE OXIDE SCALE Fracture, Ductile Behaviour and Sliding Scale Evolution During Hot Rolling, Multilayer Scales Multi-Pass Behaviour Descaling Simulation and Surface Quality 8. OXIDE SCALE MODELLING Evaluation of Interfacial Heat Transfer Effect of Chemical Composition on Oxide Scale Evolution and Scale Adhesion Ways to Maximize Descaling Effectiveness and Improvement of Surface Finish Modelling of Formation of Stock Surface and Subsurface Layers in Breakdown Rolling of Aluminium Alloys 9. OXIDE SCALE AND THROUGH-PROCESS CHARACTERISATION: INDUSTRIAL INPUT

京公网安备 11010802027623号

京公网安备 11010802027623号